Purchase BoxBolts Online - No Required Minimum

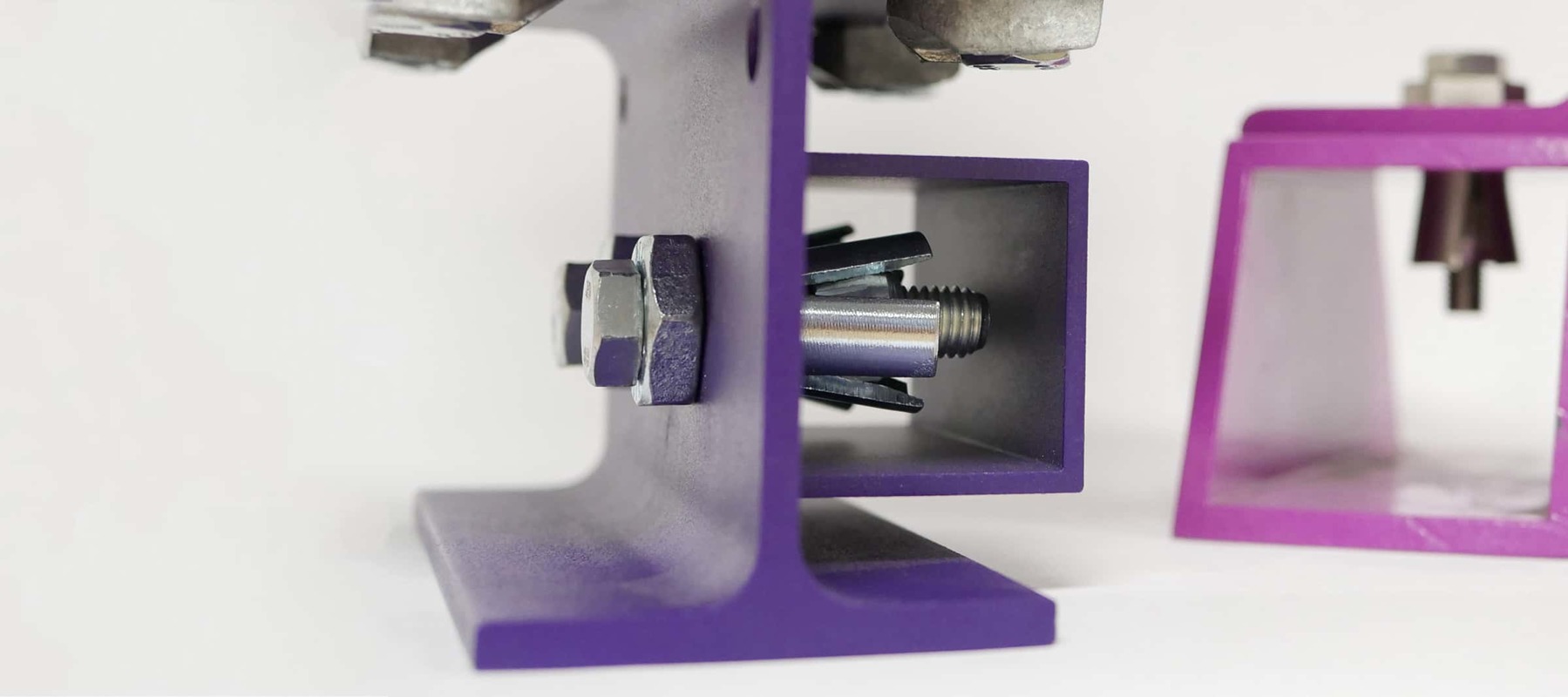

BoxBolt is the Simplest and Fastest way to Connect

to Hollow Structural Sections

Simplify Steel Connections

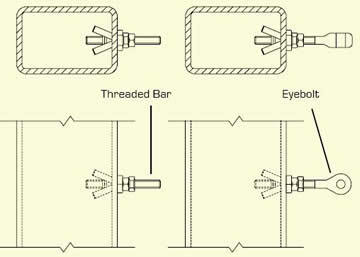

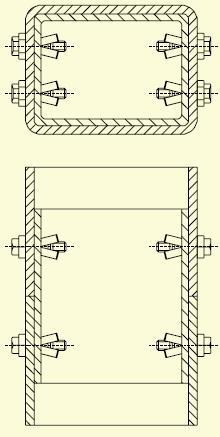

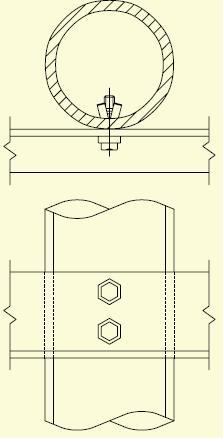

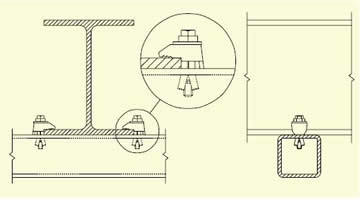

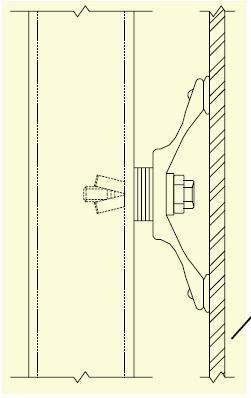

Easily install from one side of your connection, eliminating the need for rear access. BoxBolt products are structural anchor bolts which rid the need of onsite drilling or welding through bolting

Safe Solution

Unlike a welded solution, BoxBolt allows you to know exactly what your safe working loads are with a 5:1 safety factor. BoxBolts comply with International Building Codes.

Save Time on Installation

No need for a hot weld permit and only requires you to drill one hole in your structure.

How Can BoxBolts

Help Your Project

A Faster Way with BoxSok

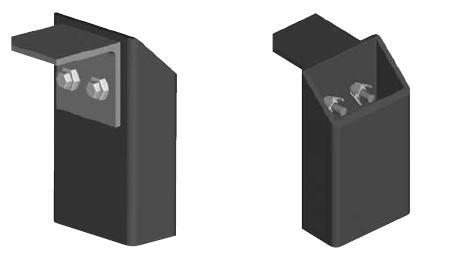

To tighten down a BoxBolt, an installer must typically use 2 wrenches to install one bolt - one to hold the outer sleeve stationary, and one to turn the inner bolt.

The BoxSok adds simplicity to the installation process. Attached to a regular socket wrench (air powered makes this a snap), it takes the place of both wrenches. The BoxSok has an outer piece that will hold the sleeve of the BoxBolt stationary, while an inner piece turns the bolt. This makes what would have been a 4 minute job (per bolt) into a 30 second job.

Learn More About BoxSok

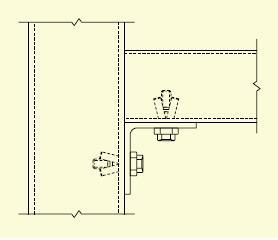

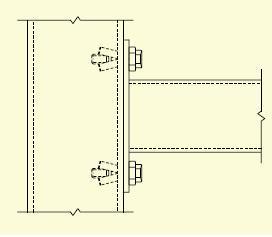

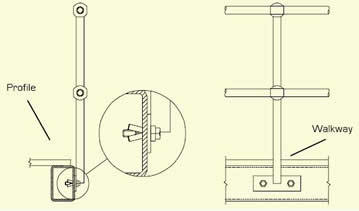

Box Bolt Installation Examples

Application Examples

The First Blind Fastener To Achieve

ICC Testing And Approval

The ESR-3217 approval document has been published on the ICC website. For a complete list of testing criteria and load ratings, download the BoxBolt catalog.

Some Specification Considerations

Clamping Range

The clamping range of the BoxBolt connector is the combined thickness of the steel being connected and the steelwork being connected to. Each diameter of the Box Bolt connector has three overlapping lengths designed to accommodate a wide range of material thicknesses. If your clamping range exceeds those stated above, special lengths are available.

Download the catalog for a complete table of clamping ranges for each bolt.

Hole Dimensions & Positioning

The clamping range of the BoxBolt connector is the combined thickness of the steel being connected and the steelwork being connected to. Each diameter of the Box Bolt connector has three overlapping lengths designed to accommodate a wide range of material thicknesses. If your clamping range exceeds those stated above, special lengths are available.

Download the catalog for a complete table of clamping ranges for each bolt.

Technical Data Sheets

Download the following data sheets for dimensional and load information

Download BoxBolt Catalog

All of the important details about BoxBolt in a print-friendly format. The BoxBolt catalog contains technical data, installation tips, and a detailed cost analysis.