11 DIY Workbench Ideas for Your Garage or Office

Thinking of building your own workbench but aren't quite sure where to start? Then, you're in right place.

In this post, we've compiled 11 DIY workbench ideas that you can use in your work area, in your garage, or in your home office.

Each of these ideas use Kee Klamp fittings and pipe for the workbench frame and are then combined with a custom table top. Unlike traditional thread-on pipe fittings, Kee Klamp fittings slide over pipe and secure down using a set screw. This makes them much easier to use and provides opportunity for adjustability.

With Kee Klamp, you can build a workbench frame specific to your exact dimensions without the need for any cutting. Then, you can simply use your table top of choice to complete the workbench. We also have a table frame few kits that you can use to make the process even simpler.

So with that said, let's take a look at a few ideas to inspire your next build:

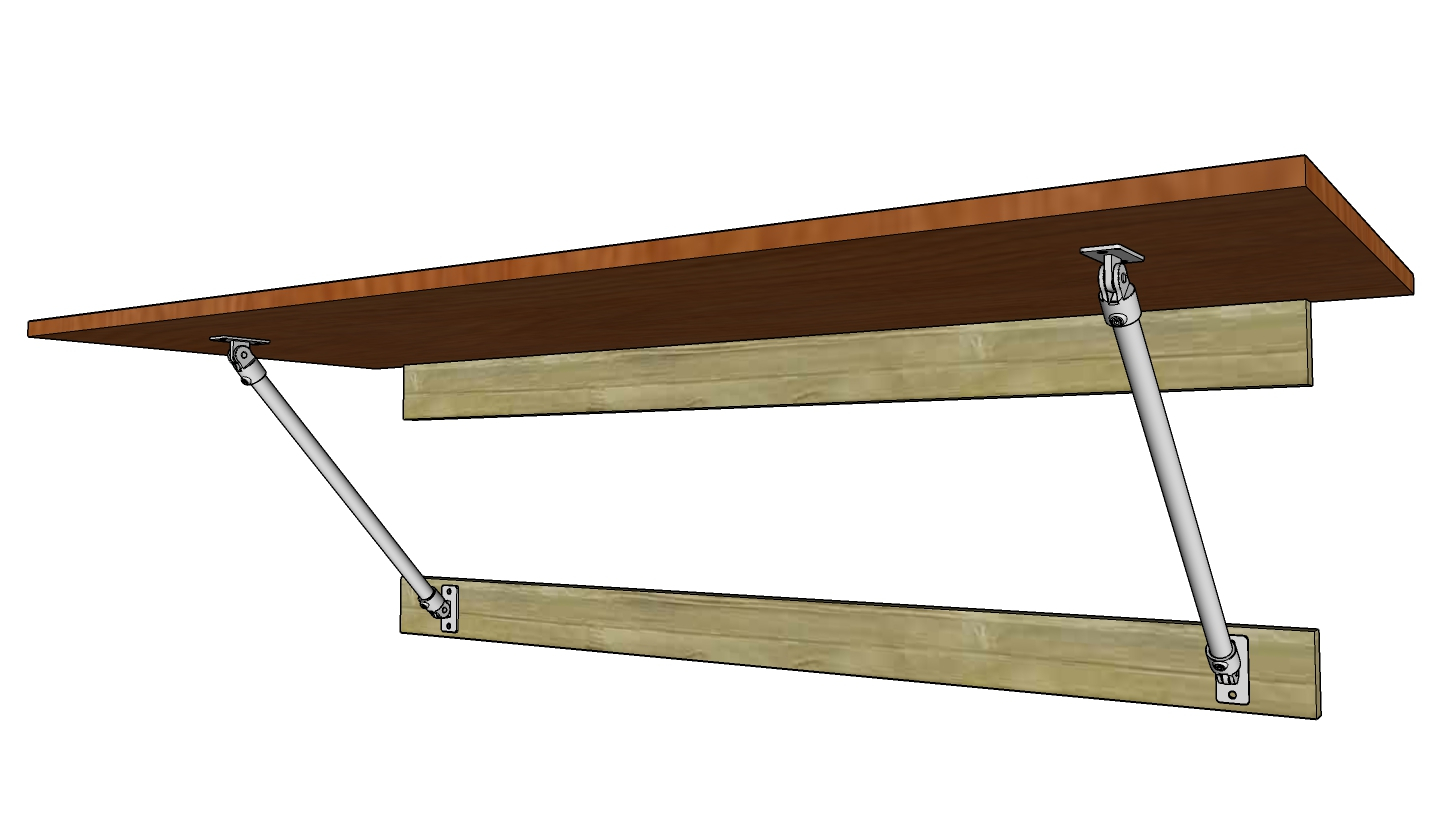

Wall Mounted Workbench

First up is this small, wall mounted workbench built by Ben in Fairfax, Virginia. The workbench features a butcher block top and makes use of the Swivel Flange fitting to mount to the wall. The Swivel Flange fitting has a range of motion of 160 degrees. It can be used to create all kinds of angles but it is a staple in wall mounted tables, desks, and workbenches.

Note that you do decide to build a wall mounted workbench, the Kee Klamp Swivel Flange and Kee Lite Swivel Flange differ in appearance. The Kee Klamp version has a rectangular mounting plate, while the Kee Lite version has a circular mounting plate. So choose the version you prefer.

Overall, Ben has been very happy with his workbench stating, "After it was complete, I just like to look at it. It looks awesome."

Specs:

- Width: Adjustable

- Depth: Adjustable

- Height: Adjustable

Assembly:

- 42 Minutes

- Allen Key, Hardware to Attach Wood to Frame

What's included:

What's not:

Office Workbench

This small workbench is used in the Simplified Building office in Germany. It features two tops that are mounted to the frame using the M50 fitting (pictured in the right corner of the image above).

At the corners of the top of the frame, the Side Outlet Elbow fitting is used and at the the corners of the second shelf, the 90 Degree Side Outlet Tee is used. Lastly, the Flange fitting is used for the workbench "feet".

Heavy Duty Workbench

This heavy-duty workbench was built by Cliff in Muskegon, Michigan. The workbench is The workbench is 36.5" high, 16' long, and 30" wide. The frame itself is 13.5' long and utilizes Size 9 (2" Outer Diameter) fittings and pipe.

We put together a full overview and tutorial for Cliff's project. Check out the full write up here.

A Common Question: How do you make a heavy-duty workbench?

Answer: The first step in making a heavy-duty, DIY garage workbench is to choose the right materials. Wood might be a more affordable option, but it won't last as long as steel. Galvanized steel pipes for the legs, supports, and frame will last for decades and give you a sturdy base. Using a steel top will prevent chips, wear, and staining that you might see on a wooden top.

Rolling Wood Top Workbench

This rolling workbench was built by Paul in Hull, Massachusetts. The workbench features a wood table top with a sliding shelf underneath. The table top is attached to the workbench frame using Flange fittings.

At the bottom of the workbench frame, locking casters are used for easy mobility. These casters are built specifically for Kee Klamp built structures. The casters slide into the open end on the pipe and can be tightened down using a wrench or by simply turning the caster until the connection is tight.

Reloading Station Workbench

This workbench was built by Jason in Plymouth, New York. Jason built the workbench as a "reloading station" so that he can reload his weapons at the bench.

To mount the table top to the workbench frame, the Flange fitting is used. To add the lower pipe support, the Single Socket Tee and 90 Degree Side Outlet Tee fittings are used.

A Common Question: How deep should my workbench be?

Answer: Typically, an arm's length is ideal for the depth of a workbench to ensure you can reach the back of the bench. This usually ranges from 28-36 inches.

Wood Top Garage Workbench

This garage workbench was built by Zach in Hollidaysburg, Pennsylvania. The workbench frame is a custom design paired with a custom built wood table top. Zach decided to spray paint the pipe black and keep the fittings in their original finish to create a unique look.

In this project, the Flange, Single Socket Tee and 90 Degree Side Outlet Tee fittings are used.

Rolling Metal Workbench

This metal top workbench was built by Joseph as mobile work table for his office/facility in Covington, Georgia. Joseph decided to use our Rugged Table Frame Kit for the workbench frame. The workbench is 96" long, 24" deep, and 34" tall.

A Common Question: What should I use for my workbench top?

Answer: The type of top for your workbench is going to depend on what the bench is used for. Wood tops are aesthetically pleasing but may not last as long as a metal/steel top. Wood is prone to splintering and staining while steel can take a pounding and is resistant to spills of chemicals, paints, or other liquids.

Workbench/Shelf

This workbench was built by Chris in Rochester, New York as a multi-function bench and shelf combo. The goal was to built the combination workbench with a $200 budget. For the workbench shelves, one 4'x8' sheet of plywood (cut into three sections) was used.

In this project, the Flange, Single Socket Tee and Side Outlet Elbow fittings are used. View the full tutorial for this project here.

DIY Garage Workbench

This workbench is one of ten in a local self-service repair shop in Virginia Beach, Virginia. The workbenches in this garage are built using Kee Klamp fittings and pipe for the frame paired with a stainless steel table top. The table tops are from Shop Storage Cabinets and are 84" wide, 24" deep, and 1 1/4" thick.

In this project, the Flange, Single Socket Tee and 90 Degree Side Outlet Tee fittings are used. Read the full write up on this project here.

A Common Question: What is a good size for a garage workbench?

Answer: Garage workbenches typically range from 28-36 inches deep, 48-96 inches long, and 28-38 inches in height. While workbenches can be customized and therefore range in various sizes, this is the typical size workbench you'll find.

U-Shaped Butcher Block Workbench

This massive U-Shaped workbench/desk combo was built by Tyson for his work office. The design is comprised of three separate tables that can be moved if needed. This gives Tyson some flexibility should he ever want to change the layout of his office.

For the table tops, Tyson used 2-1/4" maple butcher block workbench tops that he ordered online from Grizzley.com. Read the full write up on Tyson's project here.

Live Edge Workbench

Lastly, this live edge workbench was built by Doug in Livingston, Montana. The workbench table top was custom built from a 13' Douglas Fir slab and took Doug over 20 hours of sanding and finishing to complete the top.

"After 20 plus hours of sanding and finishing this 13' Douglas fir slab and cutting some pipe, the frame buildout with the Kee Klamps took a few minutes. The end result is simple and very stable", said Doug.

In this project, the Flange, Single Socket Tee and Two Socket Cross fittings are used.

Now, it's time for you to build your own workbench! Try browsing our list of fittings and our table kits to find a fit for your project.

If you need any help at all building or designing your project, don't hesitate to reach out to our projects team for help. We offer free design assistance and can help you create a project that fits your application perfectly. Our team can be reached by emailing projects@simplifiedbuilding.com or by visiting our free design assistance page here.