3 Things You Need To Know When Selecting Beam Clamps

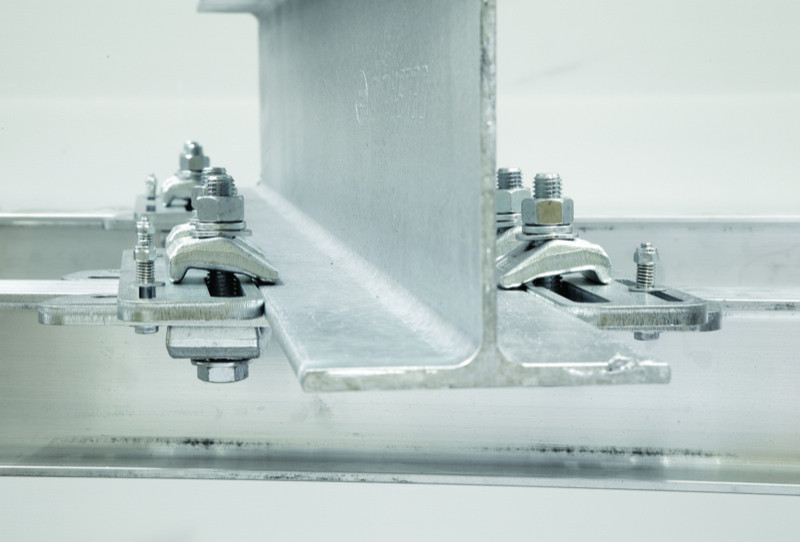

Beam clamps are the perfect solution for beam-to-beam connections. Not requiring welding or drilling, these structural connections make for quick engineering and simple installation. All parts are pre-engineered for specific loads and are installed with standard bolt assemblies. The only trick is ensuring you get the correct beam clamps for your application.

You can choose from a variety of different beam clamps to fit almost any steel beam. Choose from the standard BA and BB Clamps for w-beams to BT and BW clamps for s-beams, and even BC and BD clamps for hooking over channels and angles. We are confident that we can connect any two steel beams together in a safe and simple way.

Fortunately, there are only three pieces of information required for selecting the best clamp for your job; designations of your beams, loading information, and orientation of the connection. We will go through these one-by-one to further explain what each means.

1. Designation Of Your Beams

These beam clamps are designed for structural steel-to-steel connections. Meaning you will likely have either a w-beam, s-beam, or angle connecting to a w-beam, s-beam, or angle. Having the designation of the two beams you are clamping together will give you all the dimensions needed for selecting the right clamps.

If you are unsure or do not have the designation of your beams, there are two key dimensions needed for selecting a clamp; flange width and flange thickness.

Given that there is no welding required when utilizing these beam clamps, oftentimes for connections a location plate is needed. A location plate is a steel plate between the two beams that have holes drilled in them for the bolt assemblies to pass through. Having the beam's flange widths will inform the engineer of the exact hole spacing required for your location plate.

The flange thickness is crucial for the clamp selection. The design of the beam clamps is to lie flat on the flange of the beam. Each beam clamp comes with a “tail” that helps prop up the clamp to match the height of the flange. However, shims or packing pieces are typically required to assist in the clamp lying flush.

In conclusion, the designations of the beam or at the minimum the flange width and thickness are necessary to select the right-sized clamps.

2. Loading Information

With any steel-to-steel connection, these beams will obviously serve a purpose. That purpose will have forces applied to the connection, possibly in several different ways and directions. It is imperative that you have that loading information in mind before picking the components.

Each clamp is tested and pre-engineered to specific tensile and shear loads. This load, shown in the catalog, is per clamp. Meaning, if you have a connection that has 4 clamps/bolt assemblies, you can multiply those loads by 4.

In short, a tensile load is one that force or stress is applied perpendicularly while a shear load refers to a force being applied at a parallel orientation.

There are other forces that may be a factor in your connection other than tensile and shear. If that is the case, an engineer will need to get involved to confirm the clamps and hardware will withstand the loads.

3. Orientation of the Beam Connection

This seems like a no-brainer, however, it is important to know the orientation of the two beams you are connecting to each other. The most common orientation being perpendicular or parallel. You can fix the two beams together at any angle or pitch, you’ll just need to have those specified for additional engineering.

Also, most connections have the two beams flush against each other. If that is not the case, knowing the spacer or gap you need between the two beams would be required as well.

With these 3 bits of information, you can browse the catalog quickly and find the clamps that would be best in your situation. All the information you need is listed out in tables giving clear guidance. There are also cheat sheets on pages that will give you recommendations on the clamps and shims needed depending on your bolt size and beam dimensions.

If you need additional assistance or engineering, you can always reach out to the projects team here at Simplified.