Kee Klamp Pipe Fittings

Why Should You Choose to

Build with Kee Klamp Fittings?

Wide Variety

No matter what you are trying to build, there is probably a Kee Klamp that will fit your needs.

Easy to Use

A simple hex key is the only tool required to create a strong, rigid joint. Eliminating the need for bulky tools or welding.

Industrial Strength

Kee Klamp fittings, size 5 to 9, can support an axial load of *2000 lbs. per set screw with the set screw when tighened properly.

The Most Versatile

Pipe Connection System Available

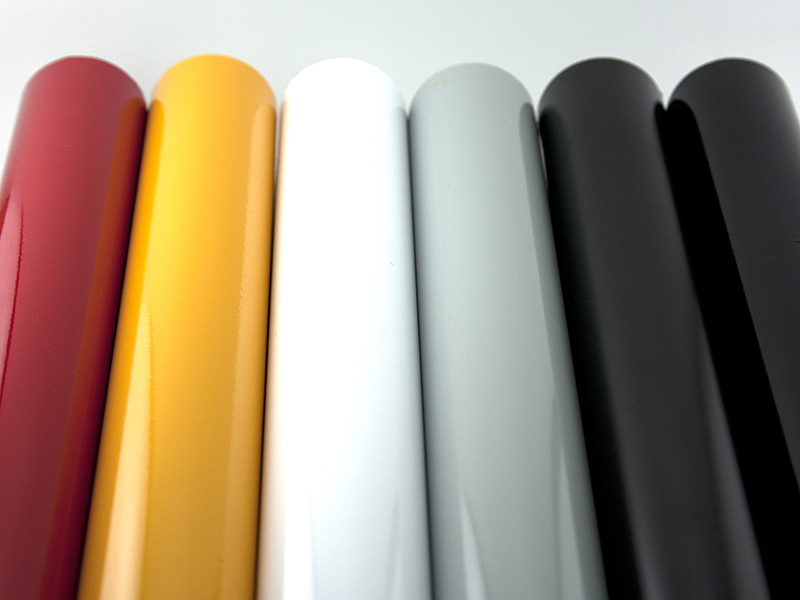

Pipe

Colors

Quality Assurance

Health and Safety

TÜV, Europe's leading Independent Testing House, has approved the following Kee Klamp fittings in sizes 5 to 9:

10, A10, 12, A12, 14, 15, 16, 17, 19, 20, 21, A21/A26, 25, 26, 27, 28, 29, 30, 35, A35, 40, A40, 45, A45, 46, F50, M50, M51, M52, BC53, 55, 56, M58, 60, 61, 62, 63, 64, 65, 67, 68,70, 75, 86, 87, 88, 89, 114, 121, 145.

The maximum load of each fitting type is as stated on the TÜV Certificate, a copy of which is available upon request. The technical descriptions featured in this manual have not been part of the testing.

Due to possible dynamic load influences, some structures will need to be checked at regular intervals to ensure set screws are correctly tightened.

For an up to date TÜV listing see https://www.keesafety.com/products/kee_klamp#testing-certifications

Kee Klamp are malleable iron castings manufactured to the requirements of ASTM A47-77-32510.

Kee Klamp fittings, size 5 to 9, can support an axial load of 2000 lbs. per set screw with the set screw tightened to a torque of 29 lbs./ft. This rating includes a safety factor of 2:1.

The exception to this torque specification is size 6 Kee Lite (Aluminum) fittings. The recommend set screw torque value for size 6 Kee Lite is: 19 ft/lbs.

No Kee Klamp fittings have been found to be hazardous within the meaning of current OSHA Regulations, assuming that the materials are cut and assembled using normal pipe cutters, saws and hexagonal keys.

Kee Klamp fittings are designed so that the need to weld is avoided - an added safety element since the welding process does have OSHA implications, especially if the pipe is pre-galvanized or has any other pre-finish.

Specifying Kee Klamp Fittings

The information contained in this manual includes everything required to produce a full specification.

Every fitting is illustrated and accompanied by a table of sizes and weights. Each fitting has a simple numerical code reference, which is unique and differentiates it from every other fitting. The code defines the type of fitting and the pipe size, or sizes, it is designed to receive.

The first number, preceeding the dash (-) identifies the type of Kee Klamp fitting.

A single digit, following the dash, defines pipe size. Two digits after the dash indicate that the fitting is designed to receive two sizes of pipe. Likewise, three digits after the dash indicate that the fitting is designed to receive three sizes of pipe. The Kee Klamp pipe size codes (a choice of eight, numbered from 2-9) are shown on pages 4 and 5 of this manual, where the Kee Klamp pipe code is related to actual pipe dimensions. (See table above).

Have a Question

About Kee Klamp?

We've helped customers build unique shelves, loft beds, ADA railings, and more.